Services

Our Quality Services

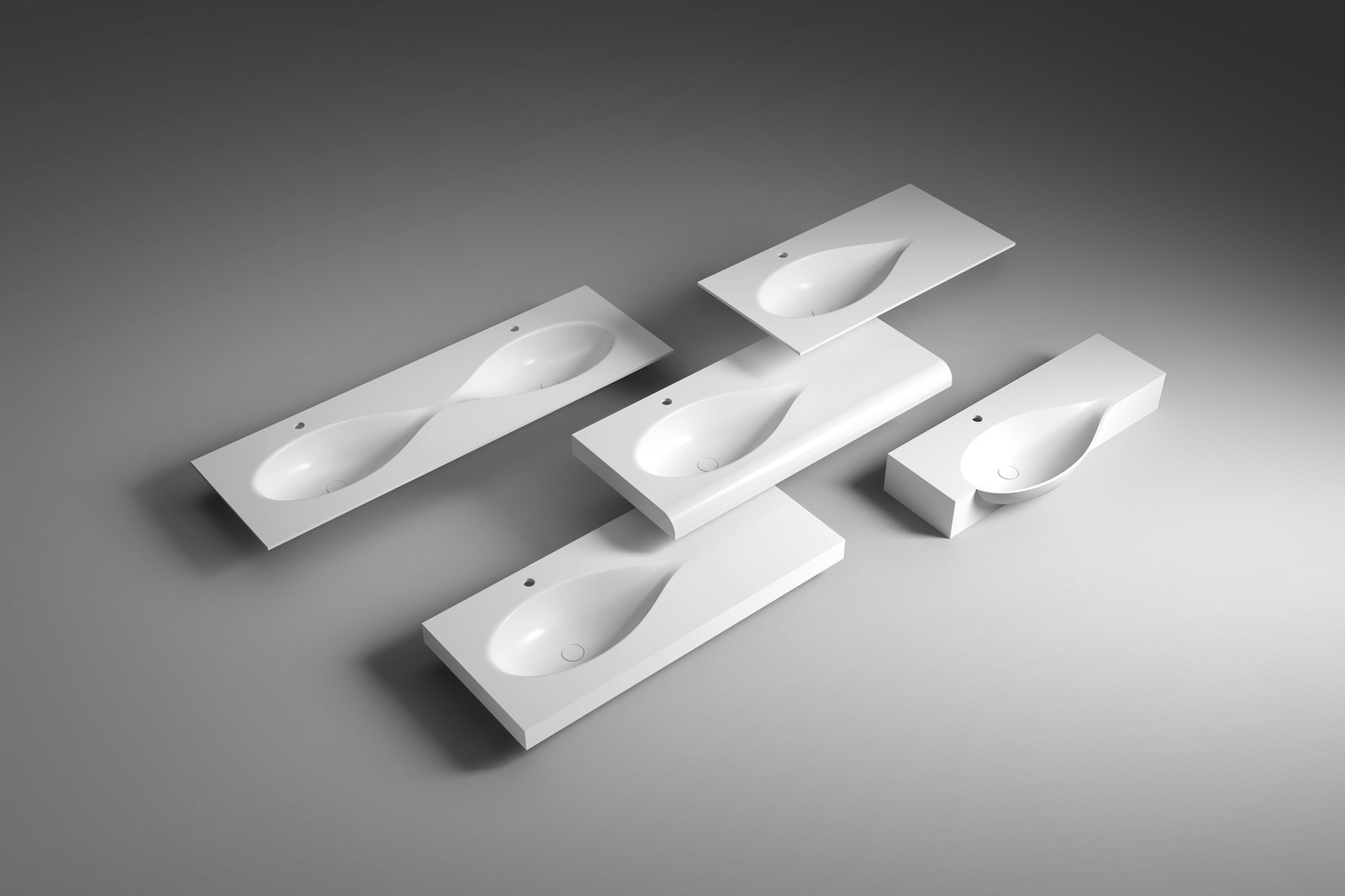

Concept Customization

Transform customers’ ideas and concepts into tangible products, from initial sketches to final production.

Tailored by Customer’s Drawings

Customers provide their own product drawings, and we develop and produce accordingly.

Customization by Dimensions

Customers provide dimensions and requirements, and we handle the entire process from design and drafting to final production.

One-Stop Solution

From concept to finished product, we provide seamless solutions that balance design, functionality, and personalized requirements.

Our Working Process

Raw Material Preparation

Main components: aluminum hydroxide powder, resin (acrylic or unsaturated polyester), curing agent, pigments. Weigh and mix according to formula.

Mixing material

Mix resin, fillers, and pigments under vacuum conditions.

vacuumize

Remove air bubbles to ensure uniformity.

Mold Preparation

Clean the mold surface.

Evenly apply release agent; optionally spray a gel coat layer to improve surface smoothness and durability.

Casting and Molding

Pour the mixed slurry into the mold.

Use vibration or pressure to remove trapped air and ensure density.

Curing and Demolding

Cure at room temperature or with heating until fully hardened. Carefully remove the bathtub from the mold to avoid surface damage.

Trimming and Drilling

Trim edges, remove burrs, and cut off excess material.

Drill overflow holes and drain holes according to specifications.

Polishing

Sand and polish the surface to achieve a smooth finish.

Inspection and Repair

Check flatness, gloss, and color consistency.

Repair minor defects with resin filler and re-polish if needed.

Final Quality Inspection

Test appearance, dimensions, strength, and stain resistance.

Approve only after passing all inspections.

Packaging and Shipping

Use pearl cotton, foam, cartons, or wooden crates for protective packaging.

Ensure safe transportation without damage.

Why Choose Us

In one word, we are professional and experienced on solid surface resin products, with competitive prices, looking forward to your cooperation.

Constant Innovation

Our top designer has over 20 years experience for sanitary ware specially for bathtub and wash basin, and his designs have got many awards and many patents for invention and appearance design. We believe that innovation is the vitality of an enterprise, so we keep constant innovation on product designs and structure, to keep attracting customer eyes, which is very helpful for marketing

High Quality

We insist in using high grade material for production, to keep high quality of the products. We believe quality is fundamental to the survival of an enterprise, so we will not give up on quality for our solid surface products.

Competitive price

Our designer concentrates on studying the structure of the bathtub, to reduce the weight of the bathtub, to save cost and at the same time keep the original performance.

Good service

Our team got very high reputation on customer service, cause we are professional and patient to customers. Once customer has any problem, we will solve it asap.

Large Capacity

We have 3 lines for injection, 5 lines for cutting and processing, 10 lines for sanding, for current capacity is 600 bathtubs per month, and will adjust the capacity according to order quantity.

Frequently Asked Questions

What is an solid surface bathtub made of?

Our bathtubs are crafted from premium resin, aluminum hydroxide, and mineral fillers, giving them the strength of natural stone with a refined modern finish. Compared with acrylic or ceramic tubs, artificial stone delivers luxury texture, durability, and excellent heat retention—perfect for a long, relaxing soak.

Is the bathtub easy to clean?

Absolutely. The surface is non-porous and antibacterial, meaning stains and dirt can be wiped away with scouring pad and water. No need for harsh chemicals—making it both eco-friendly and hassle-free.

Does your product support customization?

Of course! We provide OEM and ODM services, and can customize product specifications, packaging, etc. according to your needs

Is the bathtub heavy?

Yes, it is heavier than standard acrylic tubs—but that’s a good thing. The solid weight provides exceptional stability and a premium feel. We recommend professional installation for the best experience.

Can I customize the color or size?

Yes! We offer tailor-made solutions in size, shape, and surface finish to perfectly match your bathroom design. With our customization service, you get a bathtub that’s not just functional, but a centerpiece of your bathroom.

Do you provide matching bathroom accessories?

Yes. To create a cohesive luxury bathroom, we also provide basins, countertops, and other bathroom products in the same solid surface material.

What is the warranty period?

We provide a 3-year warranty covering material and manufacturing defects, so you can purchase with confidence.

What if the bathtub gets damaged?

Minor scratches are easy to repair with simple polishing. For more serious issues, our customer service team will provide professional repair or replacement solutions to keep your bathtub looking perfect.

CONTACT US

To continuously develop market-leading premium sanitary products, enhancing lifestyles through exceptional design and quality.